Unlock the Full Potential of Your Business with an Empanada Maker

EM400 margarine extruder

The EM400 margarine extruder is a machine built for the production of dough blocks with adjustable thickness and a sheet width of approximately 15.75 inches.

Read More

FH600 forming sheets

The FH600 is a continuous sheeting machine for forming dough sheets, starting from lumps, trimmings, or a mix of both.

Read More

LH600 Laminador Sheet

The LH600 is a continuous dough sheeting machine suitable for rolling out dough, including virgin dough, trimmings, or for incorporating filling into the dough sheet.

Read More

GAETANO Empanadas assembling

The GAETANO is a semi-automatic machine for assembling empanadas from the dough disc. Thanks to its chain transmission design, it occupies very little space.

Read More

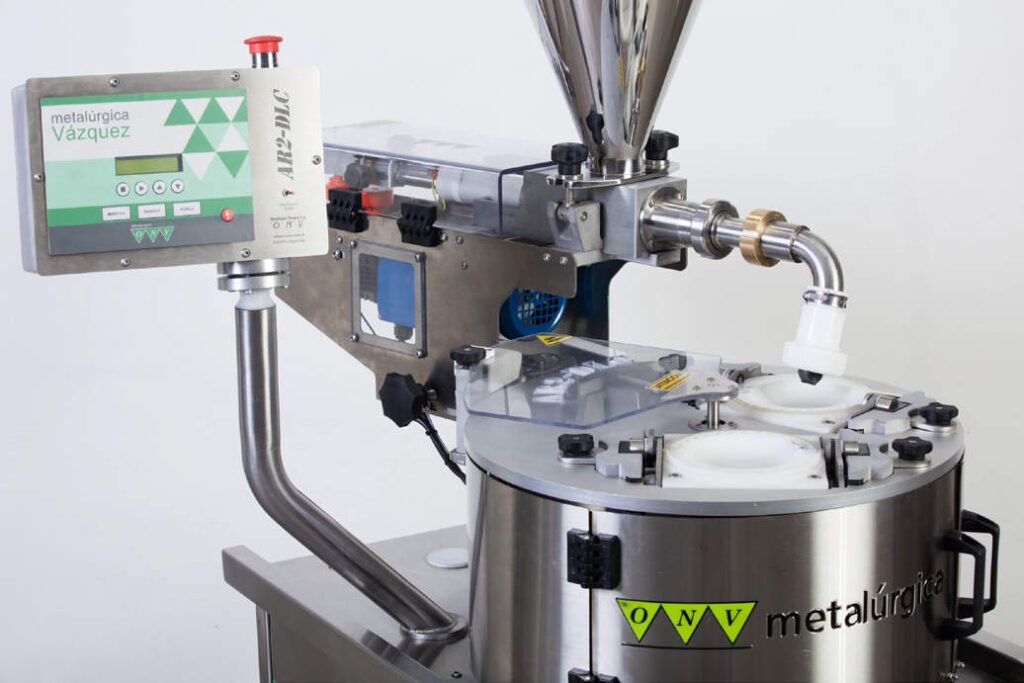

AR6D - EVO ROTARY MAKER OF PIES

The AR6-D is an automatic equipment for assembling pies based on the disc, thanks to its swivel design takes up very little space.

Read More

In today’s food industry, efficiency, consistency, and quality are critical to staying competitive. Whether you run a small café, a busy restaurant, or a large-scale food production facility, having the right tools can make all the difference. One such tool gaining popularity, especially in Hispanic and Latin American food markets, is the empanada maker.

Empanadas are loved worldwide for their versatility and delicious flavor combinations. From savory to sweet fillings, they offer the perfect balance of taste and texture. However, for businesses, making empanadas by hand can be time-consuming and labor-intensive. That’s where the empanada maker comes into play, revolutionizing production by offering speed, uniformity, and ease.

In this article, we’ll explore the key benefits of incorporating an empanada maker into your food production process.

2. Consistent Quality and Uniformity

Achieving uniformity when handcrafting empanadas can be challenging, especially as production volumes increase. Variations in size, shape, and filling can lead to inconsistency, affecting customer satisfaction.

An empanada maker ensures each empanada is consistent in size, shape, and filling quantity. This uniformity is crucial for businesses aiming to deliver a reliable product, whether serving customers in a restaurant or selling through retail channels. The machine guarantees precision, ensuring that each empanada meets your brand's quality standards.

3. Labor Cost Savings

Labor costs are a significant expense in the food industry, and manual empanada production requires skilled labor, which can be costly and difficult to find. By investing in an empanada maker, businesses can reduce their reliance on manual labor, saving money in the long run.

With an empanada maker, even a small team can handle large-scale production without compromising quality. This allows businesses to reallocate resources to other areas like marketing, customer service, or expanding their product offerings.

1. Increased Production Efficiency

One of the greatest advantages of using an empanada maker is the ability to significantly boost production. Whether you're preparing small batches or need to scale up for a high-demand event or continuous distribution, the empanada maker can handle the job.

Handmaking empanadas can be slow, requiring skilled labor to shape, fill, and seal each empanada. The empanada maker automates these tasks, drastically cutting production time. Many models allow operators to produce dozens of perfectly shaped empanadas in just minutes, freeing up time for other essential kitchen tasks.

4. Optimization of Filling Costs

An empanada maker helps optimize the precise amount of filling used in each empanada, directly reducing waste and controlling costs. Manually crafting empanadas often leads to inconsistencies in filling amounts, leading to inefficient use of ingredients and higher production costs.

The empanada maker ensures that every portion of filling is exact, thanks to its adjustable dosing systems. The machine distributes the filling uniformly, eliminating human error that could result in overfilling or poorly sealed empanadas, where the filling may spill during cooking.

5. Improved Hygiene and Food Safety

Food safety is a top priority in the food industry, and maintaining high hygiene standards is essential for any business. The automated process of an empanada maker minimizes human contact with dough and filling, helping maintain hygiene and prevent food contamination.

Additionally, most empanada makers are designed with easy-to-clean components, ensuring they can be sanitized quickly between production runs.

6. Scalability for Growing Businesses

As your business grows, so does the demand for your products. Meeting this demand without compromising quality or production time can be challenging. An empanada maker offers the scalability needed to grow your business smoothly.

Whether you're expanding your restaurant menu, entering the frozen food market, or looking to distribute empanadas to retail stores, the empanada maker helps you scale production to meet demand.

7. Energy and Resource Efficiency

Many modern empanada makers are designed to be energy-efficient, helping businesses reduce energy consumption and lower operating costs. This is especially important for large-scale production facilities where energy use can be substantial.

In addition to energy savings, the empanada maker helps reduce food waste by ensuring the exact amount of dough and filling is used, minimizing leftovers and reducing food costs.

8. Enhanced Customer Satisfaction

Ultimately, customer satisfaction is key to a successful food business. By using an empanada maker, you can consistently deliver high-quality, delicious empanadas that keep customers coming back for more. The precision of the machine ensures that each empanada is perfectly sealed, preventing filling from spilling during cooking and providing a pleasant eating experience for your customers.